To better prepare the students of the International University of Logistics and Transport (IULT) in Wrocław for leading positions in the global job market, classes in the Logistics programme are conducted in specialized information systems laboratories. Each laboratory features software for simulating logistics-related tasks and with systems supporting enterprise management.

The International University of Logistics and Transport in Wrocław is a leading institution in the TFL sector (Transport, Freight Forwarding, Logistics), thus it ensures its students gain broad and in-depth practical knowledge by studying in fully equipped specialized laboratories.

By introducing practical teaching elements and training in logistics software, the IULT students and graduates are well-prepared and valued professionals immediately upon graduation.

The University’s laboratories are equipped according to the scientific and technical facilities in three thematic areas, corresponding to the specializations within the Logistics programme:

- Vocational Centre of Excellence in Logistics

- Laboratory of Logistics Engineering

- Laboratory of Basic Technical Issues

- Laboratory of Computer Technologies

VOCATIONAL CENTRE OF EXCELLENCE IN LOGISTICS

The Vocational Centre of Excellence in Logistics responds to labour market needs in the era of the Green Deal, sustainable development, and technological change. The project has been supported under the National Recovery and Resilience Plan.

Practical classes are held in a modern logistics laboratory equipped with, among others:

- Forklift simulator – allowing the simulation of forklift operation under various, also hazardous, conditions,

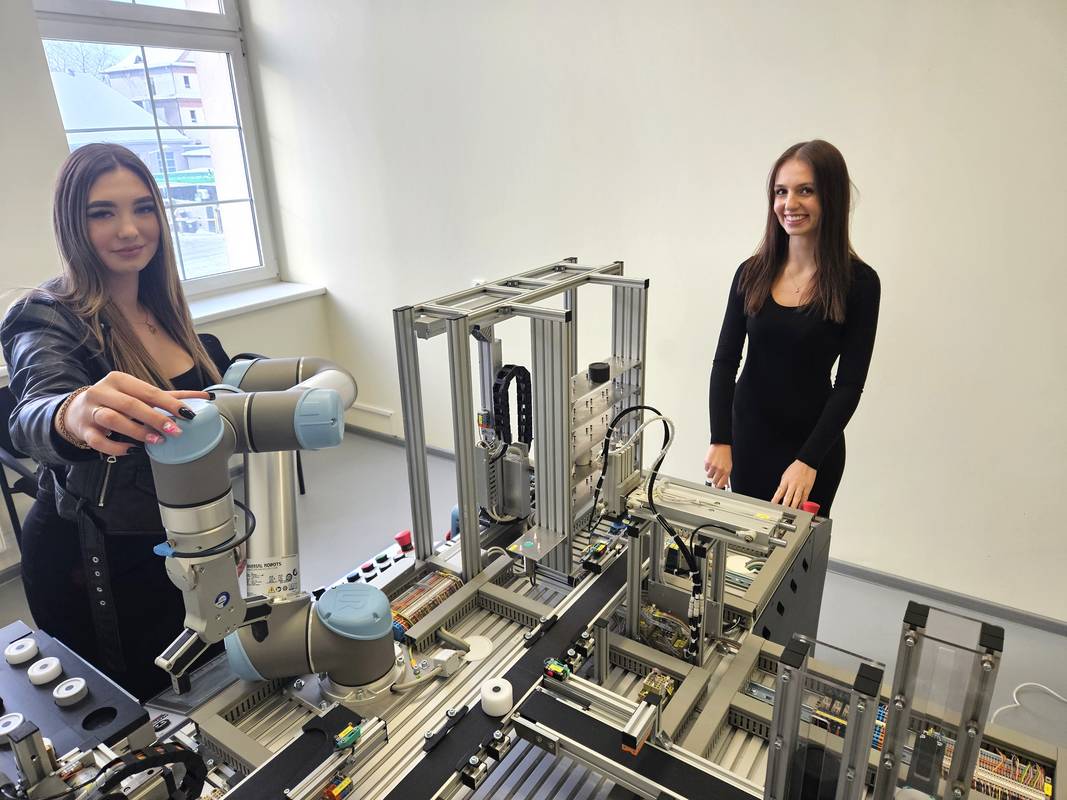

- Teaching station in production logistics – presenting transport and storage of components in the production process,

- RFID gates – with readers and label printers,

- Drones – for monitoring cargo transport,

- Exoskeletons – reducing the strain on warehouse workers.

LABORATORY OF LOGISTICS ENGINEERING

The Laboratory of Logistics Engineering covers courses in automatic identification, automation, and warehouse technologies. The programme includes experiments designed to provide hands-on experience with equipment and technologies used in industry. Classes are conducted in pairs at experimental workstations.

LABORATORY OF BASIC TECHNICAL ISSUES

The Laboratory of Basic Technical Issues was created with engineering studies in mind. It spans five rooms and covers subjects such as physics, electronics, electrical engineering, and chemistry. By supplementing the programme with practical classes at experimental stations, students have the opportunity to engage more deeply with the technical issues encountered during their studies. Working in three-person groups helps students master more difficult theoretical concepts and develops teamwork and problem-solving skills.

LABORATORY OF COMPUTER TECHNOLOGIES

The Laboratory of Computer Technologies forms the foundation for mastering essential professional tools in present reality. Provided with 7 computer labs offering individual workstations, students can learn to use software applied in logistics and transport operations, as well as acquire modelling and problem-solving skills relevant to professional practice.

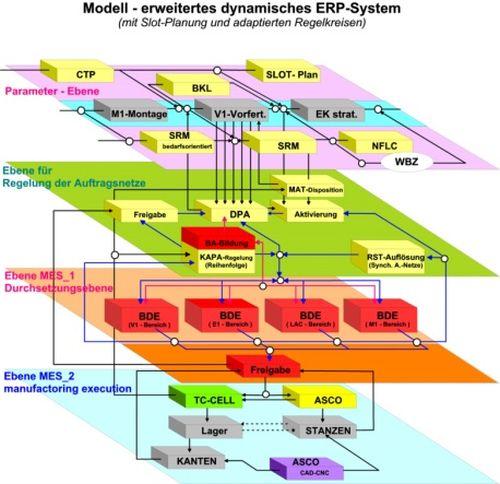

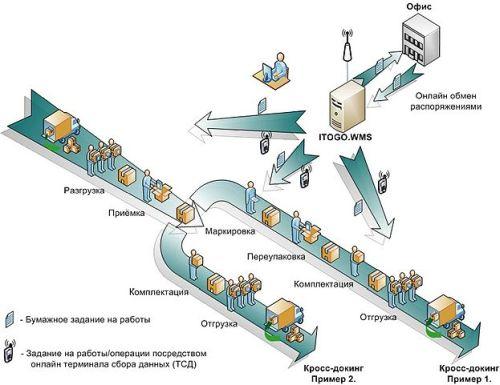

The labs are equipped with ERP and WMS systems, as well as specialized software for modelling and simulation. Systems used at the university include: SAP R/3, AnyLogic, FlexSim, TRANS.EDU, RFID, EDI, ERP, MRP, WMS.

These laboratories are didactic facilities where classes are conducted for both full-time and part-time studies.

To best prepare students for work in transport and logistics companies, laboratory stations are designed to allow them to practice specific issues in real-world conditions and understand their technical and theoretical mechanisms..

For example, students working at barcode technology stations learn not only the advantages and disadvantages of various barcode symbology but also test potential problems during implementation, which prepares them to avoid or mitigate such challenges in the future.

Classes also introduce new solutions that are still rare in industry, such as RFID. Several stations feature a variety of readers (LF, HF, UHF), both for passive and active tags, as well as industrial solutions. Different types of transponders are collected so that students can see the physical differences depending on the application and experiment with their use.

Commonly used solutions are also covered. For example, a workstation with magnetic, contact, and contactless cards has been created to bring different technologies together in one application, thus allowing for a comprehensive presentation of the topic. This helps to raise awareness of bank card use and access control solutions for secure facilities.

It is not always possible to expose students to full-scale technical facilities in their actual environments and working conditions. For such cases, model solutions have been developed using both physical objects and computer simulations. For example, in teaching, a warehouse model is used where large-scale shelving presents warehouse operations supported by WMS software. Where possible, real-life technical equipment identical to that used in actual warehouses is applied. In cases where this is not feasible due to scale, safety, or cost, software tools are used. These not only demonstrate problem-solving but also build universal skills in modelling, design, and simulation.

Therefore, computer labs are equipped with widely used industry software (such as SAP R/3) as well as tools for tackling a broad spectrum of problems (such as AnyLogic and FlexSim).

|

|

|

SYSTEMS USED AT THE IULT INCLUDE:

- TRANS.EDU

- RFID (Radio-Frequency Identification)

- EDI (Electronic Data Interchange)

- ERP (Enterprise Resource Planning)

- WMS (Warehouse Management System)

- MRP (Material Requirements Planning)

TRANS.EDU SYSTEM

The Trans.Edu system allows students to take on the role of a transport company owner. It is a platform for information exchange that ensures timely delivery of goods and on-time payments. During classes, students experience processes that reflect daily operations. The tool is used by specialists throughout Europe.

RFID (RADIO-FREQUENCY IDENTIFICATION)

RFID is a system for controlling the flow of goods through remote reading and recording of data (e.g., GUID identifiers) using electronic circuits attached to monitored objects. Sometimes referred to as a “radio barcode,” RFID also requires global unification efforts similar to those that enabled barcodes to spread worldwide.

EDI (ELECTRONIC DATA INTERCHANGE)

EDI enables the transfer of business transaction information directly from computer to computer using standardized message formats. Its aim is to eliminate repetitive data entry and increase both the speed and accuracy of information flow by connecting the relevant applications of companies participating in the exchange. It improves real-time access to logistics information, enhances data quality, and reduces process workloads. Effective use of EDI requires direct communication between buyers’ and sellers’ computer systems.

ERP (ENTERPRISE RESOURCE PLANNING)

ERP refers to integrated software systems that unify business processes across all organizational levels. ERP systems cover the entire range of processes in a company and optimize workflows in areas such as finance, HR, logistics, and production. They are designed for manufacturing, commercial, and service enterprises alike.

WMS (WAREHOUSE MANAGEMENT SYSTEM)

A WMS is a logistics program for managing product flow in warehouses, often referred to as a high-bay warehouse management system. WMS solutions coordinate warehouse operations and streamline all related processes. They are especially important for logistics providers handling large numbers of diverse shipments from many senders to many receivers on a daily basis.

MRP (MATERIAL REQUIREMENTS PLANNING)

MRP is a set of processes for determining material resource requirements (raw materials, components, etc.). Its purpose is to calculate precise material needs and delivery schedules to meet changing demand for products. Often supported by IT systems, MRP helps to reduce financial outlays in production organizations by optimizing inventory and the production process itself.

ADMISSION FOR THE 2025/2026 ACADEMIC YEAR IS OPEN

SIGN UP X